Notes - Size Reduction

Tumbling Mills

-

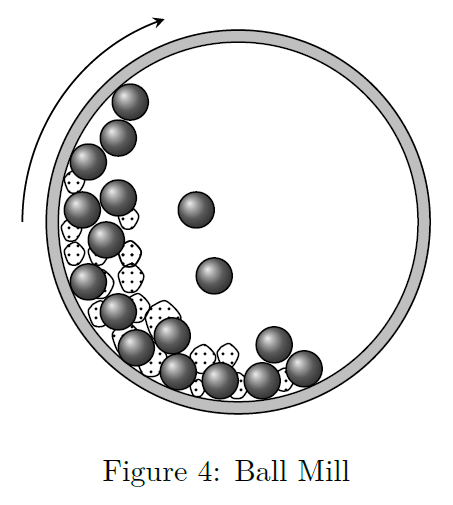

A cylindrical shell slowly turning about a horizontal axis and filled to about half its volume with a solid grinding medium forms a tumbling mill.

-

Little or no grinding is done when a mill is centrifuging, and operating speeds must be less than the critical speed.

-

Critical Speed \[n_c = \frac{1}{2\pi}\sqrt{\frac{g}{R-r}}\] where

\(n_c\) = critical speed

\(r\) = radius of ball

\(R\) = radius of ball mill

\(g\) = acceleration due to gravity -

Tumbling mills run at 65 to 80% of the critical speed, with the lower values being suitable for wet grinding in viscous suspensions. There are various forms of tumbling mills, listed as below:

-

Ball mill: or pebble mill. Refer to Fig.(4). In this, impact force is the principal size reduction force.

-

Tube mill—continuous ball mill with long cylindrical shell.

-

Conical ball mill—segregation of grinding units in a single chamber is possible.

-

Rod mill: Rod mills are very similar to ball mills, except they use long rods for grinding media. The size reduction forces are: rolling, compression, and attrition.