Notes - Agitation

-

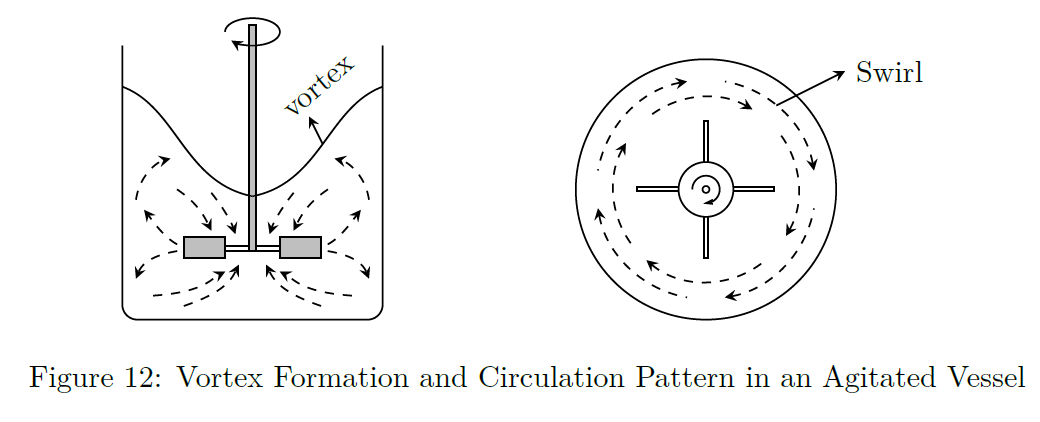

Swirling and Vortex Formation: When the shaft is vertical and centrally located in the tank, the tangential component is generally disadvantageous. The tangential flow follows a circular path around the shaft, and creates a vortex at the surface of the liquid. At high impeller speeds the vortex may be so deep that it reaches the impeller, and gas from above the liquid is drawn down into the charge. Refer to Fig.(12).

-

Prevention of Swirling

-

Impeller can be mounted off-centre. This is satisfactory for small tanks.

-

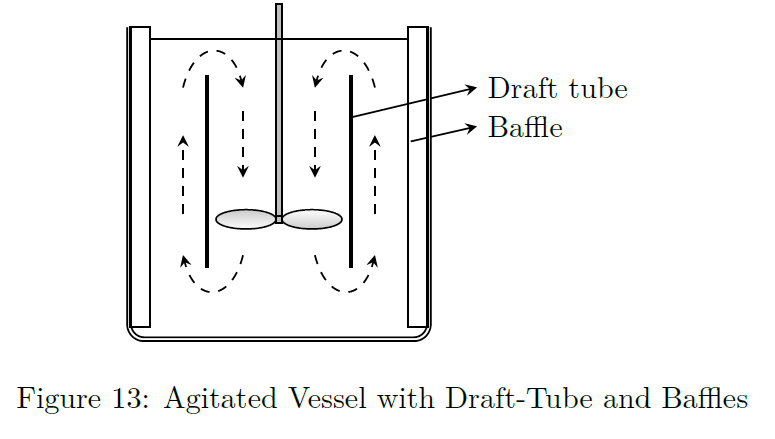

In large tanks with vertical agitators, the preferable method of reducing swirling is to install vertical baffles (usually 4 numbers), which impede rotational flow without interfering with radial or tangential flow. Baffles improve the rate of mixing, at the expense of increased power consumption.

-

Baffles are generally not required with high-viscosity liquids where gross vortexing is not a problem.

-

Typically four baffles will be used, each having a width equal to about one-tenth of the tank diameter. In some cases the baffles are mounted flush with the wall, although occasionally a small clearance is left between the baffle and the wall.

-

Draft-tube: Draft-tube is a cylindrical housing surrounding the impeller with a slightly larger diamater than the impeller. It helps to channelize the flow. Flow is from top to bottom—inside the draft-tube; and, from bottom to top—outside the draft-tube. This arrangement is needed for providing particulate solids in suspension. Refer to Fig.(13).

-