3. Chemical Process Industries

Sodium Carbonate

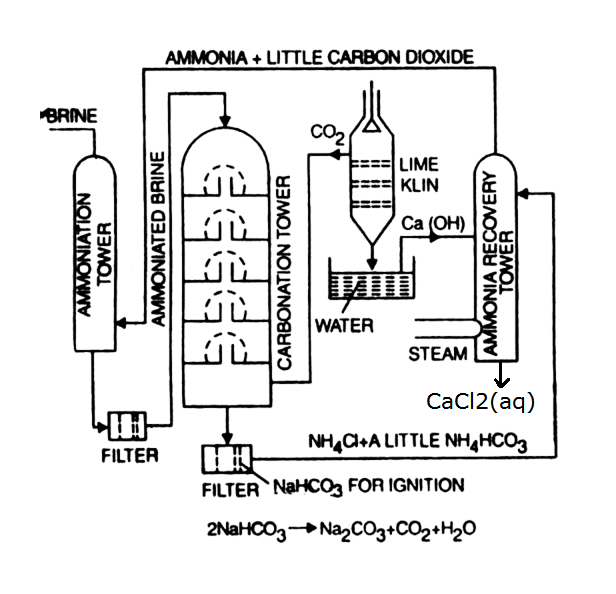

Solvay Process

Solvay process is based on the conversion of sodium chloride to sodium carbonate using ammonia and carbon dioxide.

\[\ce{NaCl} + \ce{NH3} + \ce{CO2} + \ce{H2O} \rightarrow \ce{NaHCO3} + \ce{NH4Cl}\] Ammoniated solution of salt is carbonated with \(\ce{CO2}\) from a coke-fired lime-kiln.

The precipitated sodium bicarbonate is converted to sodium carbonate by heating it, releasing water and carbon dioxide:

\[\ce{2NaHCO3} \rightarrow \ce{Na2CO3} + \ce{H2O} + \ce{CO2}\]

Ammonia is regenerated from the ammonium chloride byproduct by treating it with the milk of lime (calcium hydroxide) obtained from carbon dioxide generation:

\[\ce{2NH4Cl} + \ce{Ca(OH)2} \rightarrow \ce{2NH3} + \ce{CaCl2} + \ce{2H2O}\]

Recovery of Ammonia:

The lime-treated solution is fed to the top of the bubble-cap distillation unit. Steam is injected at the bottom, stripping out the ammonia down to a residual level of only 0.001 percent.

Calcination of \(\ce{NaHCO3}\):

The crude \(\ce{NaHCO3}\) is calcinated in dryers constructed with rotating seals and gas-tight feed and discharge mechanisms, to ensure the production of \(\ce{CO2}\) that is undiluted with air.